Ford 6.0L Power Stroke Diesel Common Failure Problems

The Ford 6.0L Power Stroke engine has a very interesting reputation but I'm not afraid to tell you that most people that go through the motions love this engine. The Ford 6.0L Power Stroke engine has become one of my favorite projects at work. You too will be a proud owner once you are familiar with the engine, how to repair it, and all the common problems and issues surrounding the 6.0L Power Stroke.

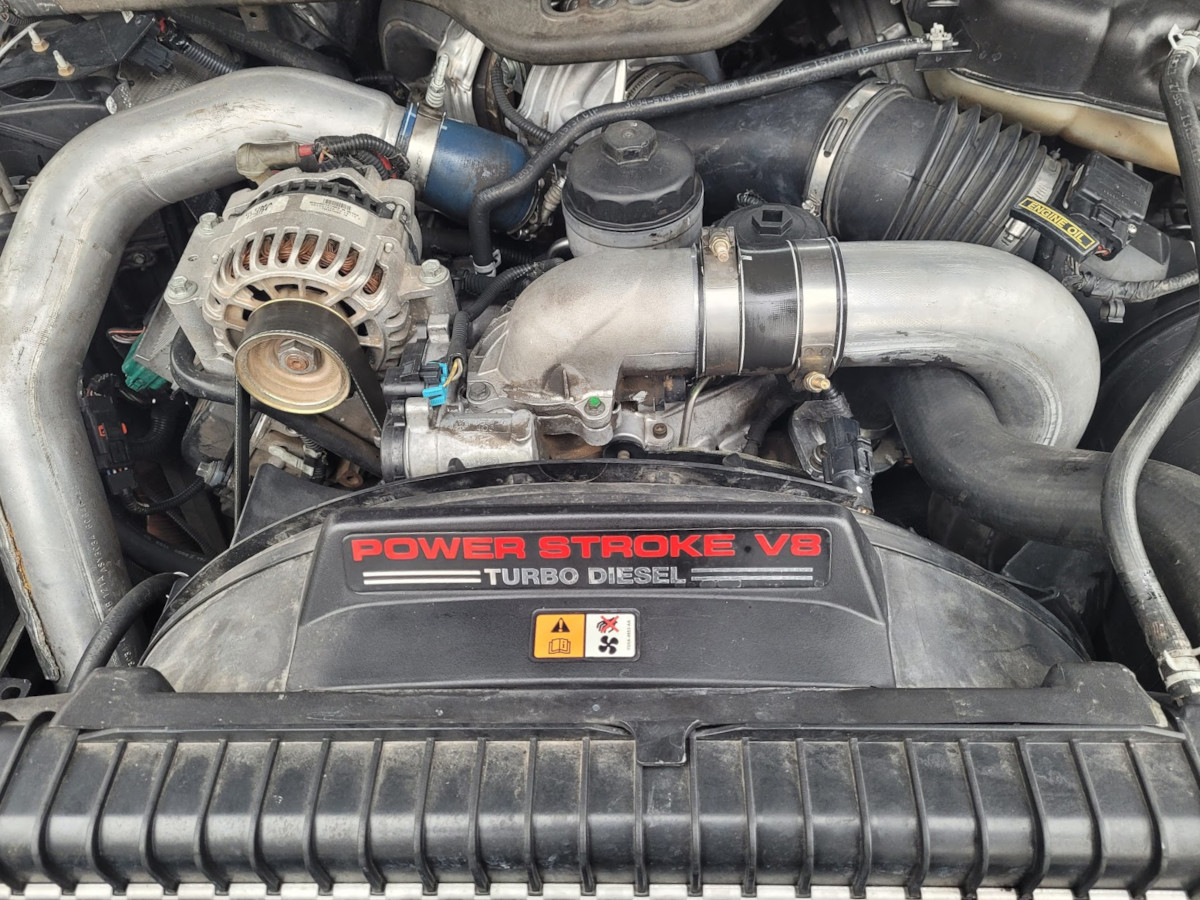

There's so many places to that I could start to describe this engine, but lets start with an overview. The 6.0L Power Stroke replaced the 7.3L Power Stroke in the middle of model year 2003. The engine has output specs that feature 325 horsepower and 570 foot pounds of torque (compared to max 275 hp and 525 ft.lbs. in late 7.3 manual trans engines). The 6.0L Power Stroke has a noticeably richer power band that gives the truck a huge performance increase and faster acceleration mostly due to the increased control from the variable geometry turbocharger.

Depending on the year of production, it varys slightly in engine design. The early versions (2003 to early 2004) feature a completely different high pressure delivery system utilizing a quick connect braided hose that attached to a unique oil rail, different intake manifold, and an ICP sensor (Injector Control Pressure sensor) mounted on the high pressure pump housing underneath the turbo.

Some of the most common issues appearing on both the early and later models of the Ford 6.0L Power Stroke engine include: oil cooler failure, EGR cooler failure, VGT Turbo failure, Fuel Injector Control Module failure, head gasket failure, and common injector failure. Fortunately, most of these major common problems fail in a logical order.

6.0L Power Stroke ICP Sensor Leaks

On 2003 / 2004 engines, because of its relative closeness to the turbo, the ICP sensor was one of biggest problems we still see constantly at the dealer. Excessive temperatures can cause the connector and/or wires to melt and sensor could also fail to seal internally causing an oil leak that also soaked the connector requiring replacement. The later models changed it up a bit by relocating the ICP to the front of the passenger side valve cover drastically reducing the failure rate. Common symptoms of a failing ICP sensor is an unsteady idle or sudden RPM jumps usually accompanied by an oil leak.

With no ICP signal, the PCM will default to pre-configured values. This can result in excessive crank time.

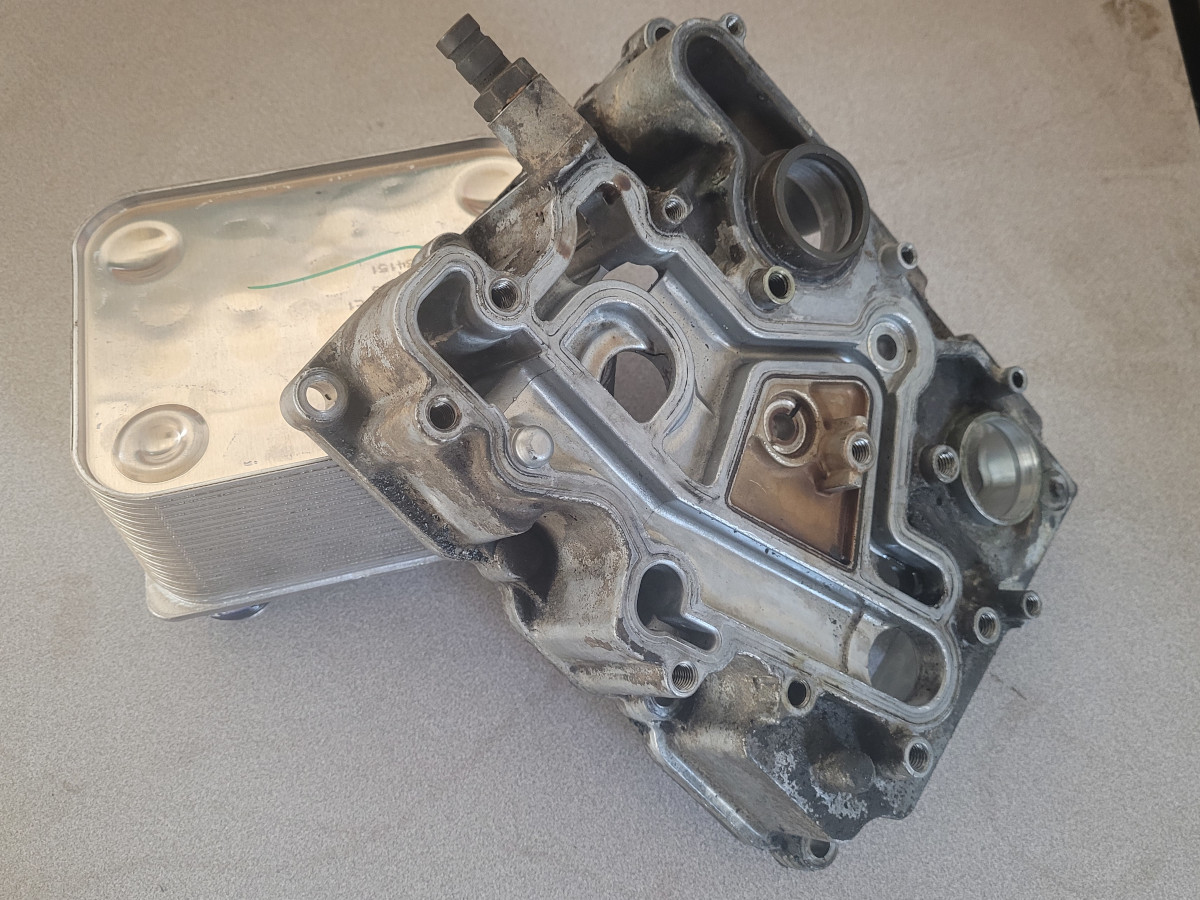

6.0L Power Stroke Oil Cooler Failure

Excessive oil temperatures cause oil to breakdown quicker resulting in less lubrication properties for the engine. The higher oil temperatures can make the failure rate much higher on other components, like other sensors and even the valves. The oil actually smells baked so you can have a good idea if the oil cooler is plugged with a simple sniff test. Diagnostic path is pretty easy using a scan tool.

6.0L Power Stroke EGR Cooler Failure

EGR cooler failure is linked to oil cooler being clogged as described above. EGR cooler becomes starved for coolant causing the tubes, welds, or fins to fail. These EGR cooler cracks allows the coolant an entry point into the exhaust or intake. Combustion heat vaporizes the coolant and causes white smoke with that burnt sweet smell. These cracks also allow exhaust pressure to enter the coolant system mimicking head gasket failure.

EGR cooler leaks can even cause a hydro-locked engine! Once the engine is off, the turbo up-pipes can become filled with coolant, the coolant then flowing back into the combustion chamber through the exhaust valve causing the hydro-locked concern. Glow plugs would have to be removed to free it.

Most people like to install EGR delete kits on their truck. Most of these kits are cheap and tend to leak at the hose overtime. Again, the failure cause generally coincides with the oil cooler so always repair both. Replacement of either the oil cooler or EGR cooler requires the 6.0L Power Stroke Intake Removal.

6.0L Power Stroke Turbocharger VGT Ring Sticking

The variable vane turbo on these engines have a tendency of getting stuck causing a severe lack of power or sluggish boost. A stuck turbo could set either a underboost or an overboost codes. The best preventative maintenance is not let it idle extended periods of time. That also means go out drive it like you stole it sometimes, pedal to the metal, forcing the turbo to make huge sweeping. Other symptoms of a stuck 6.0L turbo include a loud flutter after acceleration.

Most turbochargers can be salvaged without replacement! An easy fix is to remove and clean your turbocharger, sometimes a replacement unison ring is required. If the turbo is leaking excessive oil or has excessive shaft play, replacement of the turbocharger could be required. Other overboost situations can be caused modified PCM, a tuner.

Head gasket leaks and pressure in the cooling system

Everyone knows the 6.0L Power Stroke has head gasket issues, or at least you know now. The engine features, like most engines, torque-to-yield head bolts from the factory. Unfortunately these bolts are not strong enough for the cylinder pressures under excessive high load / high boost and will stretch. This issue is compounded by the fact that a 6.0L only has 4 (four) M14 head bolts per cylinder. Head gasket failures were not common on the 7.3 Power Stroke which has 6 bolts per cylinder, nor on the 6.4 Power Stroke which has 4 (four) M16 bolts per cylinder.

The head gaskets are even more likely to fail at higher than designed boost levels or aggressive injector timing, usually by means of a tuner. If you want to release the beast with a tuner, I suggest having ARP head studs installed with new head gaskets to better handle higher cylinder pressures. To learn more about what is needed to installing head studs and head gaskets, read my article Ford 6.0L Head Stud Installation.

Fuel Injection Control Module Failure (FICM)

The hard start cold can be caused by several issues such as bad injectors, stiction in the injectors, bad glow plugs, bad glow plug harnesses, failed glow plug control module, or failed or weak FICM - Fuel Injector Control Module. Generally a failed FICM transformer (the piece that steps the voltage up from 12v to 48+v) will cause hard starts. You need a scan tool to easily check FICM output voltage. It can be replaced as a new entire unit or you can install half shell on all but the 2003 model. Ford no longer sells a half shell, but the circuit board only is available from Dorman. The newer replacement FICM's should run slightly higher than originals and settle out to around 49 volts.

The single biggest issue quickly leading to FICM failure is a weak battery. If you notice slow crank speeds, or you constantly have to jump start your truck, you are quickly killing your FICM.

6.0L PSD Radiator Nipple Broken Off

We have all been there while repairing this engine. While you were leaning over, or struggling to get the turbocharger out, you might have inadvertently broken the radiator nipple that feeds back into the degas bottle. Radiators are expensive - so, luckily, there is a way to repair the radiator without replacement. I outlined this procedure on on my article 6.0L Radiator Nipple Repair.